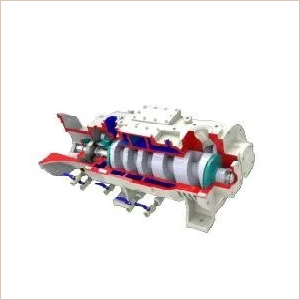

Screw Type Dry Vacuum Pump

Screw Type Dry Vacuum Pump Specification

- Power Source

- Electric

- Features

- Oil-Free, Low Maintenance, High Efficiency

- Usage

- Industrial

- Function

- Vacuum Generation

- Automatic Grade

- Automatic

- IP Rating

- IP55

- Interface

- Direct Coupled

- Application

- Chemical Processing, Pharmaceutical, Food & Beverage, Electronics

- Size

- Varies by Model

- Connectivity Type

- Hardwired

- Product Type

- Screw Type Dry Vacuum Pump

- Material

- Cast Iron / Steel

- Power Supply

- Three Phase 415V AC, 50 Hz

- Accuracy

- High Vacuum Generation

- Capacity Range

- Up to 1000 m3/hr

- Color

- Industrial Grey

- Pump Speed

- 1500 RPM

- Discharge Connection Size

- DN40 to DN100

- Drive Type

- Screw

- Inlet Connection Size

- DN50 to DN150

- Noise Level

- Below 70 dB(A)

- Moisture Handling Capability

- Good (Handles Water Vapor)

- Ultimate Vacuum

- Less than 1 mbar

- Cooling Method

- Air Cooled / Water Cooled

- Lubrication

- Dry Running (No Oil Required)

- Mounting Type

- Base Mounted

About Screw Type Dry Vacuum Pump

We are very famous for exporting and supplying a quality assured gamut of highly efficient Screw Type Dry Vacuum Pump that generates vacuum effectively. It is sourced from reliable sources of the market who are known for their quality production and reliability. Known for its excellent fuel efficiency, this sophisticated pump finds many applications in chemical, pharmaceutical and semiconductor appliances. Moreover, this energy efficient Screw Type Dry Vacuum Pump is available to our clients at fair market prices.

Features:

- Reduces evacuation time

- Less vibration production

- Optimum performance

- Strong body

Technical Specification :

| Model | | 150 | 300 | 400 | 800 |

| Displacement(50 Hz/ 60 Hz) | M3/hr | 110/130 | 250/300 | 330/400 | 660/800 |

| Ultimate pressure | |||||

| without Gas Ballast | Torr | 7.5 X 10-3 | 7.5 X 10-3 | 7.5 X 10-3 | 7.5 X 10-3 |

| with Gas Ballast | Torr | 1 X 10-2 | 1 X 10-2 | 1 X 10-2 | 1 X 10-2 |

| Motor power(50 Hz/60 Hz) | |||||

| Power Requirement | kW | 3.7 | 7.5 | 11 | 15 |

| Power Consumption | KW | 1.8/3.0 | 5.0/6.0 | 7.0/8.6 | 10.2/12.8 |

| Rotation(50 Hz/ 60 Hz) | Rpm | 2,900/3,500 | 2,900/3,500 | 2,900/3,500 | 2,900/3,500 |

| Process Connection | |||||

| Inlet Connection | JIS (ASME) | 40A (1 1/2 ") | 50A(2) | 65A (2 1/2) | 100A (4) |

| Outlet Connection | JIS (ASME) | 40A (1 1/2 ") | 40A (1 1/2 ") | 50A(2) | 65A (2 1/2) |

| Cooling water | |||||

| Max Supply Pressure | Barg | 7 | 7 | 7 | 7 |

| Pressure Drop. | Bar | 1.0 | 1.0 | 1.0 | 1.0 |

| Flow Rate | Liter / min | 5~10 | 10~15 | 10~15 | 15~20 |

| Temperature | oC | | | | |

| Connection | PT(JIS) | 1/2 " (15A) | 1/2 " (15A) | 1/2 " (15A) | 1/2 " (15A) |

| Lubricant | |||||

| Gear Oil Type | | Shell T-46 | Shell T-46 | Shell T-46 | Shell T-46 |

| Gear Oil Capacity | Liter | 1 | 1 | 1.2 | 2 |

| Bearing Grease Type | | Mobil 1 | Mobil 1 | Mobil 1 | Mobil 1 |

| Bearing Grease Capacity | Gram | 25 x 2 = 50 | 35 x 2 = 70 | 40 x 2 = 80 | 65 x 2 = 130 |

| Seal Type | |||||

| High Vacuum(HV) Seal | | Single Lip Seal + Single Lip Seal + Single Lip Seal | |||

| Low Vacuum(LV) Seal | | Lip Seal & Mechanical Seal + Gas Purge Seal | |||

| Seal Pure Gas | |||||

| Supply Pressure | Barg | 0.5~7 | 0.5~7 | 0.5~7 | 0.5~7 |

| Flow Rate | Liter / min | 5~15 | 5~15 | 5~20 | 5~20 |

| Connection | | 1/4 Tube | 1/4 Tube | 1/4 Tube | 1/4 Tube |

| Noise Level(50/60 Hz) | dB | 79/85 | 79/85 | 79/85 | 79/85 |

| Vibration(max.) | mm/s | 1.8 | 1.8 | 1.8 | 2.8 |

| Weight (Bare Shaft) | Kg | 190 | 290 | 370 | 580 |

| Inlet Purge (Option) | |||||

| Supply Pressure | Barg | 0.5~7 | 0.5~7 | 0.5~7 | 0.5~7 |

| Connection | PT (JIS) | 1/2 " (15A) | 1/2 " (15A) | 1/2 " (15A) | 1/2 " (15A) |

| Solvent Flush (Option) | |||||

| Flow Rate | Liter / min | 2 | 2 | 2 | 2 |

| Connection | PT | 1/4" | 1/4" | 1/4" | 1/4" |

| Gas Ballast (Option) | |||||

| Supply Pressure | Barg | 0.5~7 | 0.5~7 | 0.5~7 | 0.5~7 |

| Connection | PT (JIS) | 1/2 " (15A) | 1/2 " (15A) | 1/2 " (15A) | 1/2 " (15A) |

Efficient Oil-Free Vacuum Solution

This dry screw vacuum pump offers a pristine, oil-free environment by utilizing advanced dry running technology. Suitable for processes where contamination is a concern, it comes equipped with a quiet operation and high moisture tolerance. Its versatile design ensures compatibility with air or water cooling and fits a range of industrial settings, streamlining vacuum processes across various sectors.

Designed for Industrial Demands

Robust construction using cast iron or steel ensures durability under tough conditions. The direct-coupled screw drive and base-mounted configuration maximize operational stability. With its wide capacity range and automatic controls, this vacuum pump caters to the precise needs of chemical, pharmaceutical, electronics, and food industries while maintaining energy efficiency and minimal maintenance requirements.

FAQs of Screw Type Dry Vacuum Pump:

Q: How does the screw type dry vacuum pump achieve oil-free operation?

A: The pump utilizes a dry running screw mechanism, which eliminates the need for oil lubrication. This design ensures the process air remains uncontaminated and maintenance requirements are significantly reduced, making it ideal for sensitive industrial applications.Q: What makes this vacuum pump suitable for handling water vapor?

A: This vacuum pump is engineered with good moisture handling capability. Its screw technology and robust construction allow it to efficiently process gases with high water vapor content without the risk of corrosion or performance loss.Q: When should you choose air-cooled versus water-cooled options?

A: Air-cooled models are best suited for installations with limited water supply or where easy setup is preferred. Water-cooled versions provide enhanced cooling for demanding, continuous operations or high ambient temperatures, helping to maintain optimal performance.Q: Where can this dry vacuum pump be installed in an industrial facility?

A: Designed with a base-mounted configuration and direct coupling, the pump can be installed on factory floors in areas dedicated to vacuum generation. Its hardwired connectivity and IP55 protection rating make it suitable for various industrial environments across chemical, pharmaceutical, and electronics plants.Q: What process improvements does this pump bring to vacuum generation?

A: The pumps automatic operation, high vacuum accuracy, and efficient screw drive contribute to energy savings, consistent vacuum levels, and reduced downtime. The oil-free and low-maintenance design leads to cleaner processes and lower lifecycle costs.Q: How is this vacuum pump typically used in industrial applications?

A: Industries employ this pump for vacuum drying, distillation, material handling, packaging, and degassing. Its high throughput and vacuum integrity support critical processes in food & beverage, pharmaceuticals, and chemical manufacturing.Q: What are the key benefits of choosing this vacuum pump for your operation?

A: Key benefits include oil-free operation, minimal maintenance, low noise levels, and high operational efficiency. Its rugged material options (cast iron/steel), high moisture tolerance, and broad capacity range make it a versatile and cost-effective solution for industrial vacuum requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry Screw Vacuum Pump Category

Dry Screw Vacuum Pump

Size : Standard / Customizable

Connectivity Type : Direct Power

Capacity Range : From 25 to 1500 m/hr

Color : Blue / Grey

Application : Pharmaceutical, Chemical Process, Food Processing, Vacuum Packing

Load : Up to 1500 m/h

Send Inquiry

Send Inquiry