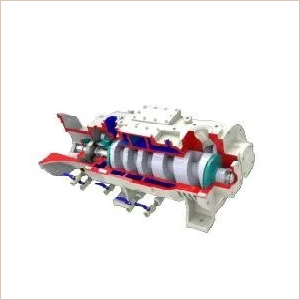

Dry Screw Vacuum Pump

Dry Screw Vacuum Pump Specification

- Size

- Standard / Customizable

- Power Source

- Electric

- Features

- Oil-Free, Low Maintenance, Compact Design, Robust Construction

- Function

- Dry Vacuum Generation

- Connectivity Type

- Direct Power

- Automatic Grade

- Automatic

- Application

- Pharmaceutical, Chemical Process, Food Processing, Vacuum Packing

- IP Rating

- IP54

- Usage

- Industrial Use

- Product Type

- Dry Screw Vacuum Pump

- Material

- Cast Iron, Stainless Steel

- Power Supply

- Three Phase, 415V, 50Hz

- Load

- Up to 1500 m/h

- Accuracy

- High Vacuum Accuracy

- Capacity Range

- From 25 to 1500 m/hr

- Color

- Blue / Grey

- Operation Mode

- Continuous

- Mounting

- Base Mounted

- Drive Type

- Direct Coupled

- Service Support

- On-Site & Remote

- Noise Level

- < 75 dB(A)

- Inlet Connection

- DN40 to DN100, Flanged

- Seal Type

- Non-Contact Mechanical Seals

- Pump Rotation Speed

- 1800 rpm (Typical)

- Ultimate Vacuum

- Up to 0.05 mbar

- Cooling Type

- Air Cooled / Water Cooled

- Maintenance Requirement

- Minimal

- Lubrication

- Dry, No Oil Required

- Temperature Range

- 5C to 40C

About Dry Screw Vacuum Pump

Known for providing utmost satisfaction to clients, we, Langoo Engineering Solutions Pvt. Ltd, are the leading exporter and supplier of world class Dry Screw Vacuum Pump. Our organization always prefer to source this pump from reliable vendors in order to maintain our quality. The provided pump has extensive applications for both scientific and industrial purposes such as in vehicle motors, gyroscopes and hydraulic brakes. This Dry Screw Vacuum Pump is available to our patrons at suitable market prices.

Features:

- Requires very less lubrication

- Fine mesh wires

- Reliable operation

- Extremely durable

Technical Specification :

| Model | 150 | 300 | 400 | 800 | |

| Displacement(50 Hz/ 60 Hz) | M3/hr | 110/130 | 250/300 | 330/400 | 660/800 |

| Ultimate pressure | |||||

| without Gas Ballast | Torr | 7.5 X 10-3 | 7.5 X 10-3 | 7.5 X 10-3 | 7.5 X 10-3 |

| with Gas Ballast | Torr | 1 X 10-2 | 1 X 10-2 | 1 X 10-2 | 1 X 10-2 |

| Motor power(50 Hz/60 Hz) | |||||

| Power Requirement | kW | 3.7 | 7.5 | 11 | 15 |

| Power Consumption | KW | 1.8/3.0 | 5.0/6.0 | 7.0/8.6 | 10.2/12.8 |

| Rotation(50 Hz/ 60 Hz) | Rpm | 2,900/3,500 | 2,900/3,500 | 2,900/3,500 | 2,900/3,500 |

| Process Connection | |||||

| Inlet Connection | JIS (ASME) | 40A (1 1/2 ") | 50A(2) | 65A (2 1/2) | 100A (4) |

| Outlet Connection | JIS (ASME) | 40A (1 1/2 ") | 40A (1 1/2 ") | 50A(2) | 65A (2 1/2) |

Versatile Oil-Free Vacuum Solution

Engineered for reliability and efficiency, the dry screw vacuum pump provides oil-free vacuum generation for a wide range of industrial uses. Its robust build and high vacuum accuracy make it suitable for sensitive applications such as pharmaceuticals, chemical processing, and food packaging, reducing contamination risks and maintenance downtime.

Low-Maintenance and Durable Design

With minimal servicing needs and non-contact mechanical seals, this vacuum pump is designed for continuous, trouble-free operation. Its compact footprint and direct-coupled drive allow for easy installation, while the high-quality cast iron and stainless steel components ensure long-lasting durability, even under heavy industrial loads.

FAQs of Dry Screw Vacuum Pump:

Q: How is the dry screw vacuum pump installed and connected?

A: The pump is supplied as a base-mounted unit with flanged inlet connections (DN40 to DN100). It requires a three-phase, 415V, 50Hz power supply and direct connectivity to your facilitys electrical system. Installation is straightforward, with options for standard or customized sizing based on operational needs.Q: What are the primary benefits of choosing an oil-free dry screw vacuum pump?

A: Oil-free operation eliminates the risk of oil contamination, reduces environmental impact, and significantly lowers maintenance costs. The pump operates cleanly, ensuring high vacuum accuracy and reliability for processes where product purity and a contaminant-free environment are essential.Q: When should I opt for air-cooled versus water-cooled versions?

A: Air-cooled models are ideal for installations where water is not readily available or water conservation is a priority. Water-cooled versions are better suited for environments with higher ambient temperatures or where extra cooling efficiency is required to maintain optimal performance.Q: Where can this vacuum pump be used in industrial applications?

A: The dry screw vacuum pump is well-suited for pharmaceutical manufacturing, chemical processing, food processing, and vacuum packing. Its oil-free, high-accuracy vacuum capability makes it applicable in industries requiring clean, efficient, and continuous vacuum generation.Q: What is the typical maintenance process for this vacuum pump?

A: Thanks to its non-contact mechanical seals and dry operation, routine maintenance is minimal. Standard procedures generally include periodic inspection, cleaning of accessible parts, and checking electrical connections. On-site and remote service support is available for troubleshooting or repairs as needed.Q: How does the pump maintain a low noise level during continuous operation?

A: The pumps advanced engineering, direct-coupled drive, and robust construction help keep operational noise below 75 dB(A), ensuring a quieter workplace environment, even during round-the-clock industrial operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry Screw Vacuum Pump Category

Screw Type Dry Vacuum Pump

Interface : Direct Coupled

Accuracy : High Vacuum Generation

Features : OilFree, Low Maintenance, High Efficiency

Function : Vacuum Generation

Connectivity Type : Hardwired

Power Supply : Three Phase 415V AC, 50 Hz

Send Inquiry

Send Inquiry